1.0ACCREDITATION / REGISTRATION

INORGANIC VENTURES is accredited to ISO Guide 34, "General Requirements for the Competence of Reference Material Producers" and ISO/IEC 17025, "GeneralRequirements for the Competence of Testing and Calibration L aboratories".Inorganic Ventures is also an ISO 9001 registered manufacturer (SAI Global FileNumber 010105).

2.0 PRODUCT DESCRIPTION

Product Code:Single Analyte lon Chromatography Solution

Catalog Number:ICBEN1

Lot Number:K2-0103099

Matrix:H2O

Value / Analyte(s):1 000 μg/mL

ea:Benzoate

Starting Material:Benzoic Acid

Starting Material Lot#:MO09220JO

Starting Material Purity:99.9204%

3.0CERTIFIED VALUES AND UNCERTAINTIES

Certified Value:1000 + 4 μg/mL

Certified Density:0.999 g/mL

(measured at 20士1 °C)

Assay Information:

Assay Method #1 1000土3 μg/mL

Calculated NIST SRM 84k Lot Number: 84k

Assay Method #2 1000土3 μg/mL

IC Assay NIST SRM traceable to 84K Lot Number: traceable to 84K

一The Calculated Value is a value calculated from the weight of a starting material that has been certifieddirectly Vs. a National Institute of Standards and Technology (NIST) SRM/RM. See Sec 4.2 for balancetraceability.

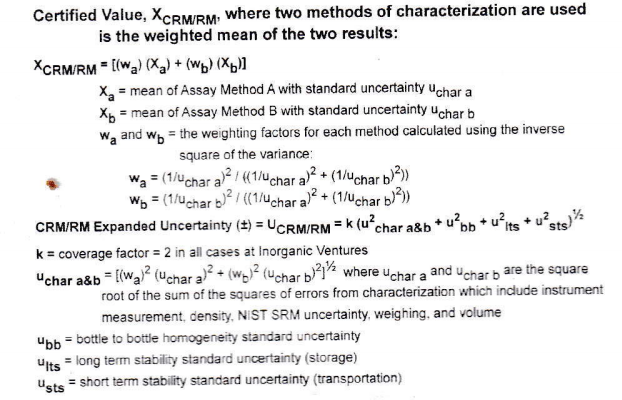

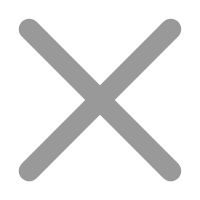

The flwin equations are used in the calculation of the crified value and the uncertainty. Reported uncerantes representexpanded uncertainties expressed at approximately the 95% confidence level using a coverage factor of k=2.

Characterization of CRM by two independent methodsCharacterization of CRM/RM by Two Methods

Characterization of CRM by one method Characterization of CRM/RM by One Method

4.0TRACEABILITY TO NIST

- This product is traceable to NIST via an unbroken chain of comparisons. The uncertainties for each certifedvalue are reported, taking into account the SRMRM uncertainty error and the measurement, weighing andvolume dilution errors. In rare cases where no NIST SRM/RM are available, the term 'in-house std.' isspecifed.

4.1 Thermometer Calibration

- AI thermometers are NIST traceable through thermometers that are calibrated by an accredited calibrationlaboratory.

4.2 Balance Calibration

- All analytical balances are calibrated by an accredited calibration laboratory and procedure. The weightsused for testing are annually compared to master weights and are traceable to NIST.

4.3 Glassware Calibration

- An in-house procedure is used to calibrate all Class A glassware used in the manufacturingandquaitycontrol of CRM/RMs.

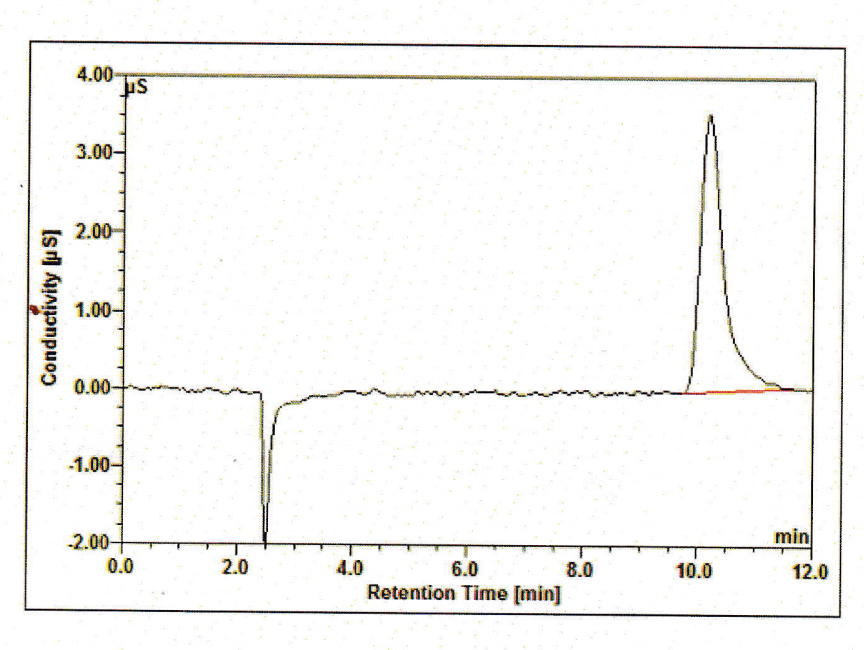

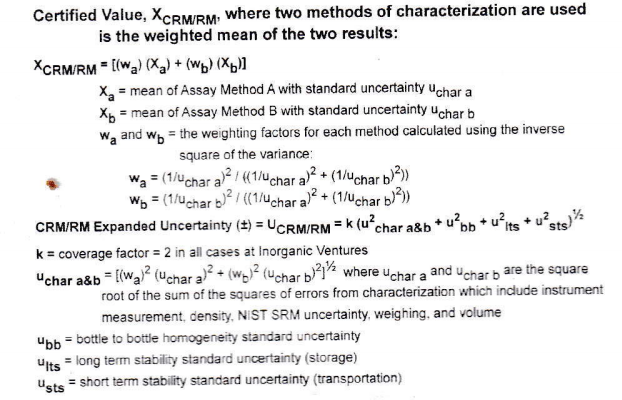

5.0CHROMATOGRAM

6.0INTENDED USE

- For the calibration of analytical instruments and validation of analytical methods as appropriate.

7.0INSTRUCTIONS FOR THE CORRECT USE OF THIS REFERENCE MATERIAL

7.1 Storage and Handling Recommendations

Store between approximately4° - 30° C while in sealed TCT bag.

- While stored in the sealed TCT bag, transpiration of this CRM/RM is negligible. After opening the sealed TCTbag transpiration of the CRMRM will occur, resulting in a gradual increase in the analyte concentration(s). It isthe responsibility of the user to account for this effect. When the bottle is weighed both before and after beingplaced in storage, the mass difference observed will be a measure of transpiration mass loss.

- After opening the sealed TCT bag keep cap tighty sealed when not in use. Store and use at20°土4° C. Donot pippette from the container. Do not return removed aliquots to container.

. For more information, visit

8.0 HAZARDOUS INFORMATION

- Please refer to the Safety Data Sheet for information regarding this CRM/RM.

9.0HOMOGENEITY

- This solution was mixed according to an in-house procedure and is guaranteed to be homogeneous.Homogeneity data indicate that the end user should take a minimum sample size of 0.2 mL to assurehomogeneity.

10.0QUALITY STANDARD DOCUMENTATION

10.1 10CFR50 Appendix B . Nuclear Regulatory Commission

- Domestic Licensing of Production and Utilization Facilities

10.2 10CFR21 . Nuclear Regulatory Commission

- Reporting defects and Non-Compliance

10.3 ISO 9001 Quality Management System Registration

- SAI Global File Number 010105

10.4 ISO/IEC Guide 17025 "General Requirements for the Competence of Testing and Calibration Laboratories"

- Chemical Testing - Acredited / A2LA Certificate Number 883.01

10.5 ISO Guide 34 "General Requirements for the Competence of Reference Material Producers"

- Reference Material Producer - Accredited / A2LA Certificate Number 883.02

11.0CERTIFICATION, LOT EXPIRATION AND PERIOD OF VALIDITY

11.1 Period of Validity

- Sealed TCT Bag Open Date:

- This CRMRM should not be used longer than one year from the date of removal from the aluminized bag oraffter the date given in Sec. 11.2, whichever comes first. This is contingent upon the CRM/RM being handledand stored in accordance with the instructions given in Sec 7.1.

Section 1. Identification of the substance/mixture and of the companylundertaking

1.1. Product identifier

Product Name:ICBEN1

Product Description:1000 μg/mL Benzoate

1.2. Relevant identified uses of the substance or mixture and uses advised against _

Recommended Use:Laboratory chemicals

Uses advised against:No information available

1.3. Details of the supplier of the safety data sheet

Company

Inorganic Ventures

300 Technology Drive

Christiansburg, VA 24073

web: www.inorganicventures.com

Section 2. Hazards identification

2.1. Classif cation of the substance or nixture

REGULATION (EC) No 1272/2008

This mixture is classified as not hazardous according to regulation (EC) 1272/2008 [GHS]

Classification according to EU Directives 67/548/EEC or 1999/45/EC

Symbol(s)

Not dangerous

GHS

For the full text of the R phrases mentioned in this Section, see Section 16

2.2. Label Elements

Product identifier

This mixture is classified as not hazardous according to regulation (EC) 1272/2008 [GHS]

Signal Word

None

2.3. Other information

No information available

Section 3. Composition/information on ingredients

3.1 Substances

For the full text of the R phrases mentioned in this Section, see Section 16

For the full text of the H-Statements mentioned in this Section, see Section 16

Section 4. First aid measures

4.1. Description of first-aid measures

Inhalation:Move to fresh air.

Skin Contact:Wash off immediately with soap and plenty of water removing all contaminated clothes andshoes.

Ingestion:Clean mouth with water and afterwards drink plenty of water.

4.2. Most important symptoms and effects, both acute and delayed

Most Important Symptoms/Effects Asthma-like and/ or skin alrgy-like symptoms.

4.3. Indication of any immediate medical attention and special treatment needed

Notes to Physician:Treat symptomatically

Section 5. Fire-fighting measures

5.1. Extinguishing media

Suitable Extinguishing Media

Use extinguishing measures that are appropriate to local circumstances and the surrounding environment.

Unsuitable Extinguishing Media

No information available

5.2. Special hazards arising from the substance or mixture

Thermal decomposition can lead to release of iritating gases and vapors

5.3. Advice for firefighters

As in any fire, wear self-contained breathing apparatus and full protective gear.

Section 6. Accidental release measures

6.1. Personal precautions, protective equipment and emergency procedures

Personal Precautions

Ensure adequate ventilation.

Advice for emergency responders

Ensure adequate ventilation.

6.2. Environmental precautions

Prevent further leakage or spillage if safe to do so.

6.3. Methods and materials for containment and cleaning up

Methods for Containment Prevent further leakage or spillage if safe to do so.

Methods for Cleaning Up Take up mechanically and collect in suitable container for disposal.

6.4. Reference to other sections

See Section 12: ECOLOGICAL INFORMATION.

Section 7. Handling and storage

7.1. Precautions for Safe Handling_

Technical measures/Precautions

Ensure adequate ventilation.

Hygiene Measures

Handle in accordance with good industrial hygiene and safety practice.

7.2. Conditions for safe storage, including any incompaibilities

Technical measures/Precautions

Keep container tightly closed in a dry and wel-ventilated place.

Section 8. Exposure controls/personal protection

8.1. Control parameters

Exposure Limits

Derived No Effect Level (DNEL) No information available.

Predicted No Effect Concentration No information available.(PNEC)

8.2. Exposure controls

Engineering Measures:Ensure adequate ventilation, especially in confined areas.

Personal protective equipment

Eye/Face Protection:Tightly ftting safety goggles.

Hand Protection:Impervious gloves.

Skin and Body Protection:Long sleeved clothing.

Respiratory Protection:When workers are facing concentrations above the exposure limit they must useappropriate certified respirators.

Environmental Exposure Controls No information available.

Section 9. Physical and Chemical Properties

Information on basic physical and chemical properties

| Physical State |

Liquid |

| Appearance |

Clear / Colorless |

| Odor |

Odorless |

| Property |

Values |

| pH VALUE |

No data available |

| Melting Point/Range |

No data available |

| Boiling Point/Range |

100°C |

| Flash Point |

No data available |

| Evaporation rate |

No data available |

| Flammability (solid, gas) |

No data available |

| Vapor Pressure |

No data available |

| Vapor Density |

No data available |

| Relative Density |

No data available |

| Specific Gravity |

No data available |

| Water Solubility |

Miscible |

| Partition coefficient: n-octanol/water |

No data available |

| Autoignition Temperature |

No data available |

| Decomposition Temperature |

No data available |

| Viscosity |

No data available |

| Explosive Properties |

No information available |

| Oxidizing Properties |

No information available |

| Other information |

|

| VOC Content |

No information available |

Section 10. Stability and reactivity

10.1. Reactivity

No data available.

10.2. Chemical Stability_

Stable under normal conditions.

Explosion Data

10.3. Possibilily of Hazardous Reactions

Hazardous Polymerization

Hazardous polymerization does not occur.

Hazardous Reactions

None under normal processing.

10.4. Conditions to Avoid

None known.

10.5. Incompatible materials

Reducing agents

10.6. Hazardous Decomposition Products

Section 11. Toxicological information

11.1. Information on toxicological effects

Acute Toxicity

| Product Information |

Product does not present an acute toxicity hazard based on known or supplied information. |

| Inhalation |

There is no data available for this product. |

| Eye Contact |

There is no data available for this product. |

| Skin Contact |

There is no data available for this product. |

| Ingestion |

There is no data available for this product. |

| Unknown Acute Toxicity |

0% of the mixture consists of ingredient(s) of unknown toxicity. |

| Skin corrosion/irritation |

No information available. |

| Eye damage/irritation |

No information available. |

| Sensitization |

No information available. |

| Mutagenic Effects |

No information available. |

| Carcinogenic effects |

No information available. |

| Reproductive Toxicity |

No information available. |

| STOT - single exposure |

No information available. |

| STOT - repeated exposure |

No information available. |

| Aspiration Hazard |

No information available. |

Section 12. Ecological info rmation

12.1. Toxicity

0% of the mixture consists of components(s) of unknown hazards to the aquatic environment

12.2. Persistence and degradability

No information available.

12.3. Bioaccumulative potential.

No information available.

12.4. Mobility in soil

Mobility in soil

No information available.

12.5. Results of PBT and vPvB assessment

No information available.

12.6. Other adverse effects.

Section 13. Disposal considerations

13.1. Waste treatment methods_

| Waste from Residues/UnusedProducts |

Dispose of in accordance with local regulations. |

| Contaminated Packaging |

Do not re-use empty containers. |

| Other Information |

According to the European Waste Catalogue, Waste Codes are not product specific, butapplication specific. Waste codes should be assigned by the user based on the applicationfor which the product was used. |

Section 14. Transport information

| IMDG/IMO |

|

| 14.1. UN-No |

Not regulated |

| 14.2. Proper Shipping Name |

Not regulated |

| 14.3. Hazard Class |

Not regulated |

| 14.4. Packing Group |

Not regulated |

| Description |

Not applicable. |

| 14.5. Marine Pollutant |

None. |

| 14.6. Special Provisions |

None. |

| 14.7. Transport in bulk according . to Annex II of MARPOL 73/78 andthe IBC Code |

No information available. |

| RID |

|

| 14.1. UN-No |

Not regulated |

| 14.2. Proper Shi pping Name |

Not regulated |

| 14.3. Hazard CIass |

Not regulated |

| 14.4. Packing Group |

Not regulated |

| Description |

Not applicable. |

| 14.5. Environmental hazard |

None |

| 14.6. Special Provisions |

None |

| ADR |

|

| 14.1. UN-No |

Not regulated |

| 14.2. Proper Shipping Name |

Not regulated |

| 14.3. Hazard Class |

Not regulated |

| 14.4. Packing Group |

Not regulated |

| Description |

Not applicable. |

| 14.5. Environmental hazard |

None |

| 14.6. Special Provisions |

None |

| ICAO |

|

| 14.1. UN-No |

Not regulated |

| 14.2. Proper Shipping Name |

Not regulated |

| 14.3. Hazard Class |

Not regulated |

| 14.4. Packing Group |

Not regulated |

| Description |

Not applicable. |

| 14.5. Environmental hazard |

None |

| 14.6. Special Provisions |

None |

| IATA-DGR |

|

| 14.1. UN-No |

Not regulated |

| 14.2. Proper Shipping Name |

Not regulated |

| 14.3. Hazard Class |

Not regulated |

| 14.4. Packing Group |

Not regulated |

| Description |

Not applicable |

| 14.5. Environmental hazard |

None |

| 14.6. Special Provisions |

None |

注:证书信息仅供参考,以产品附带证书为准。

甲氨基阿维菌素苯甲酸盐

编号:SPL-BG-018-003 CAS号:155569-91-8 规格:500mg 浓度:%

甲氨基阿维菌素苯甲酸盐

编号:SPL-BG-018-003 CAS号:155569-91-8 规格:500mg 浓度:%